Pearl-brightness chromium plating

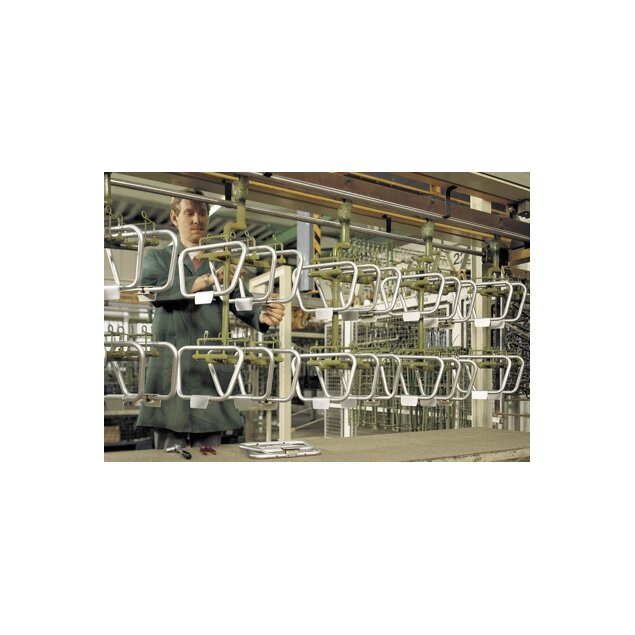

Diverse machine components with pearl-brightness chromium plating

The term is misleading because to be technically correct this process involves nickel plating with pearl-brightness (satin finish) and subsequent chromium plating. Items treated in this way acquire a very attractive appearance, whereby to a large extent small surface defects in the material become "invisible”.

Applications for this process are found e.g. in the furniture industry and a lot of technical areas where this is needed for design reasons or a non-dazzling effect is required.

Depending on requirements, a typical layer structure consists of approx. 10-30 µm pearl-brightness nickel and approx. 0.3-0.5 µm chromium. Nowadays, the copper undercoating which used to be customary (with subsequent mechanical polishing to acquire brightness) is dispensed with by and large because modern high-power baths are able to produce a sufficient degree of levelling and brightness, and copper with the same overall thickness does not increase resistance to corrosion.

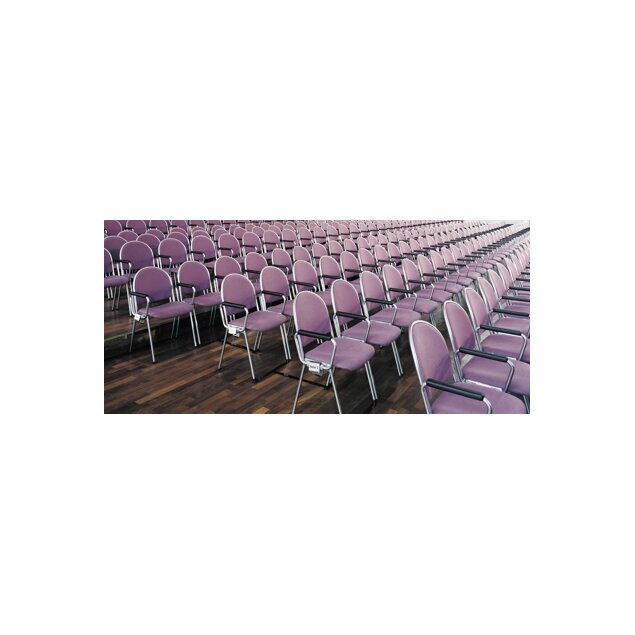

Of course, the basic material must be free of scores and scratches if this process is to produce a decorative appearance. If necessary, mechanical damage as occurs on the chair arms shown here must be removed by grinding and brushing.

| Maximum workable size of item in mm | |||

| Length | Width | Height | |

| Pearl-brightness chromium plating | 2500 | 300 | 800 |

Contacto

Rohde AG

Industriestrasse 9

D - 37176 Nörten-Hardenberg

Tel.: +49 (0) 5503 9860-0

Fax: +49 (0) 5503 9860-11

Opening hours (CET)